Blast carboblocks Pvt. Ltd.

We are among those few graphite equipment manufacturing companies that have a fully integrated manufacturing setup for making almost all types of graphite process equipment covering practically the whole range needed by the CPI.

Years Of Undefeated Success

Blast Carboblocks Pvt Ltd was incorporated in 1982. In the 4 decades of existence the technocrat based company has developed 15 products in the service of High Corrosion Chemical Process Industry, especially Pharma, Speciality chemical and Agrichemical sectors.

Company had purchased Patent rights from Bhabha Atomic Research Centre Trombay, Mumbai for the manufacture of synthetic graphite articles. The Basic process is shown on the right side.

BLAST CARBOBLOCKS is among those few graphite equipment manufacturing companies that have a fully integrated manufacturing setup for making almost all types of graphite process equipment covering practically the whole range needed by the CPI. Its products are backed by a highly focused group of R&D set up. Its Market survey group always gets an advance feel of rapidly changing scenario of chemical industries. The data on changing needs and demands of industry are fed to the R & D wing to keep them in a fast response mode for appropriate product modifications. The Technical Service Cell gives free consultancy for product applications.

Certified By

We have grown with the graphite

Equipment’s Performing in last 5 years

Manufacturing annual HTA capacity

Team of the Experienced Professionals

BCARV - Graphite Reactor

Reaction vessels in use for corrosive chemicals may have linings like glass, ceramics or polymerics, which are resistant to many chemicals but poor in heat transfer. Whereas most of the chemical reactions require either heating or cooling or both depending upon the process needs. BLAST CARBOBLOCKS has introduced the concept of chemical resistant cum heat conductive lining by transforming graphite into impervious BCARV-A1 graphite and graphite cement, very economically.

Design

Design and fabrication of reaction vessels is done as per ASME Pressure Vessel code section VIII DIVISION1 and conforming to BIS as well. BCARV reactors are especially designed to take care of the variation in thermal expansion of the graphite and MS Shell. US Military AD Specification N2 are also referred to prevent any leakage from or to the service media. Reactors with non standard L/D Ratio can also be manufactured as per Customer requirement or design.

BCAHEX - Heat Exchangerr

BCAHEX heat exchanger series is the most advanced design of polyblock Heat Exchangers. These are constructed from identically formed impervious graphite blocks with two types of passages viz short radial passages of 100 to 150mm length converging into a central cavity and short length axial passages with remixing of all the axial tube fluids in a mixing cum redistribution channel every 150 to 300 mm travel of the axial fluid. This particular feature of hydraulic design gives abundant turbulence even at low flow rates and enhances the ‘U’ and reduces the fouling & scaling drastically.

The effect of high ‘U’ and lower fouling coefficient ‘s’ is that for the same heat duty the HTA value is lower. Due to their main features of robustness, high mechanical strength and exceptionally long working life, these heat exchangers are widely used in Pharmaceutical Industries, pesticide and fumigant sectors, Dye Stuffs, other Chemical Process Industries, petrochemicals, Phosphate Fertilisers and Pickling lines of Steel Rolling Mills etc.

BCAFFA - Film Absorber

Chemical reactions releasing HCl gas are common in chemical process industry. The absorption of HCl gas to make concentrated HCl solution offers dual benefits of meeting Environment Protection Standards and Value recovery benefits.

Owing to the high heat of solution of HCl gas, the absorption has to be accompanied with cooling. The use of packed bed scrubber and a cooler for obtaining 30% HCl involves high pumping cost as well as large surface area equipment due to the limitation of permissible temperature rise per pass for effective absorption. Hence an FFA type equipment is more energy efficient. The BCAFFA system offered by BCPL has got the following unique advantages.

BCAFFE - Film Evaporator

For many processes and operations, concentrated acid or solution is produced using evaporation techniques. Dilute acid or solution can be concentrated by evaporating excess amount of water from it. For value recovery cum pollution abatement projects the BCAFFE Graphite Falling Film Evaporator is the main work horse. Its special characteristics such as: Compactness, High ‘U’, Non fouling anti-stick surface morphology, and overall cost payback period are very attractive

It is therefore first and foremost choice with the designers of pollution control and effluent treatment systems. The units have been in operation for the concentration of corrosive chemical solutions and acids viz. Sulphuric Acid, Tartaric Acid, Oxalic Acid etc. It also finds application for concentration of solutions prior to crystallization step e.g. recovery of Sulphanillic Acid from spent sulphuric acid solution.

BCADIL - Acid Dilution Unit

Generally Sulphuric Acid of 98% concentration is produced in DCDA process. However many applications require dilute acid. On dilution of Sulphuric Acid very large quantity of heat is evolved calling for an efficient heat removal design. Dilute Sulphuric Acid is very corrosive too. BCARDIL meets both the challenges cost effectively. The dilution of Sulphuric Acid from 98% to 70% concentration is achieved with high efficiency and in a corrosion free manner.

Construction

Dilution unit comprises of a mixing chamber at the top of the equipment followed by a heat exchanger as an integral part of the equipment.

Mixing Chamber is a BCAHEX hollow cylindrical impervious graphite block with baffles inside it. 98% sulphuric acid is mixed with De-mineralised Water (DMW) in the mixing chamber. 60% of the mixing process gets complete in this chamber.

BCACON - Conc. System

Multi-effect concentration systems are designed and developed by BCPL in view of value recovery from spent acid effluent generated in dyestuffs and Pharmaceuticals industries. Under new environmental protection standards disposal of untreated spent acid effluent is prohibited. The lime treatment cost of spent acid is very sizeable. The BCACON system achieves value recovery by concentrating Sulphuric acid up to 70% or more concentration and at the same time treatment cost of effluent is offset by the saleable product recovery to a large extent.

Beside value recovery BCACON system is designed for concentration of other corrosive acids and also for pre crystallization heating.

Application

- Tartaric Acid concentration.

- Oxalic Acid concentration.

- Phosphoric Acid concentration.

- Recovery of Sulphanillic Acid from spent acid solution.

BCAHCL - Recovery System

Construction

The system contains following equipments: BCAFFA Graphite Falling Film Absorber, TGS Graphite tail gas packed bed scrubber.

Similar to BCAHEX heat exchanger, BCAFFA absorber comprises of pile of graphite blocks with headers at both the ends. It differs in basic design from BCAHEX in respect of a distributor block, provided at the top of the BCAFFA. The absorber is followed by a Tail Gas Scrubber. The tail Gas Scrubber is a typical packed bed column in Graphite construction.

Operation

The absorbent liquor is distributed uniformly by the distributor block of the BCAFFA.

The absorbent forms a thin uniform film along the curved wall of holes of the top block, while flowing down to the next block.

BCARUP - Rupture Disc

Introduction

“Safe Operational Practice” calls for protection of every pressure vessel against pressure excursions caused due to abnormal process dynamics related conditions. In many cases it is possible to fit a pressure relief device using two rupture discs on two separate legs of a “U” stand on a single opening on the reactor or a pipeline. BCARD Graphite based Rupture discs can be used with a variety of advantages.

Features

- Rupturing pressure reduces only by 10% from room temperature to 1500C.

- The rupturing pressure reduces by 9% only in 10,000 hours of exposure to 80% value of rated rupturing pressure.

- Pressure range- Normally 1.5bar – 8bar. Special Rupture Discs can also be made as per demand / design by party.

- BCARD shows rupture pressure deterioration of one order of magnitude lower than the conventional metallic rupture discs of Nickel etc.

BCADC - Distillation Column

Introduction

Distillation operations are often carried out at higher temperatures. When it involves corrosive chemical duty, the selection of MOC becomes limited to costly exotic materials. Graphite has the unique property of very high resistance to corrosive chemicals even at elevated temperature. BCADC graphite lined distillation columns are highly recommended for this type of chemical duty. BCADC packed bed columns are especially designed to reduce pressure drop.Tower height is smaller compared to plate columns for similar chemical duty conditions. For the inherent reasons of operating ease in case of low height towers the BCADC is preferred over plate type columns.

Construction and Design

BCADC distillation columns are designed and constructed according to the chemical duty involved.

Number of active sections and height of each section is determined as per the degree of separation required. Packings are supported on Grid plates.

Top section of the column consists of a reflux distributor. It uniformly distributes the reflux in the top packing section. Liquid re-distributor is provided between each active section.

BCASC - Bed Scrubber

Introduction

BCASC graphite packed columns are extensively used for absorption of corrosive and hazardous gases. The column is packed with graphite raschig rings. BCASC units are widely used in a number of chemical process industries viz. Pharmaceuticals, Dye Stuffs, Pesticide, Heavy Chemicals, Bulk Drugs, etc.

Construction

A typical BCASC column consists of a cylindrical Impervious Graphite BCARV-A1 shell. There are support plates inside this shell to hold the packing material in position. A liquid distributor provides effective irrigation of the packing. The effective section is packed with graphite raschig rings. Type & size of packing and the height of bed are determined as per loading and flooding characteristics of the scrubbed and scrubbing fluid.

Providing Products To Various Industries

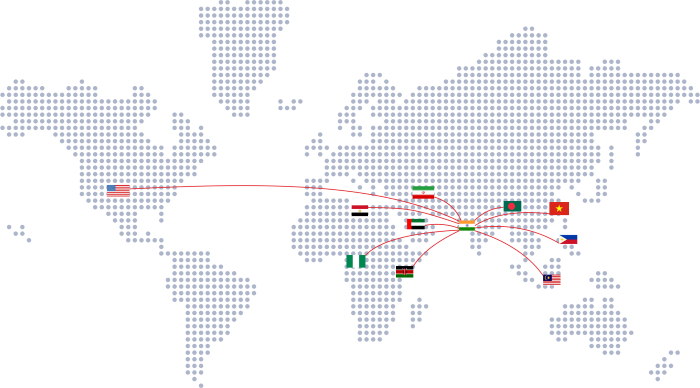

Our Global Footprints

our Clients

Visit Us At